Soil Boring with auger apparatus

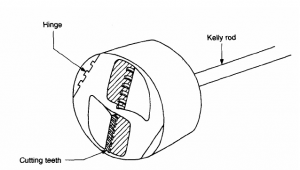

Augers may be classified as either bucket augers or flight augers. Bucket augers are similar in construction to the flat-bottomed Sprague and Henwood barrel auger. They consist of an open-topped cylinder which has a base plate with one or two slots reinforced with cutting teeth, which break up the soil and allow it to enter the bucket as it is rotated.

The top of the bucket is connected to a rod which transmits the torque and downward pressure from the rig at ground level to the base of the hole: this rod is termed a ‘Kelly’. Bucket augers are used for subsurface exploration in the USA, but are rarely used for this purpose in the UK. This is probably because they require a rotary table rig, or crane-mounted auger piling rig for operation, and this is usually expensive to run. Casing also provides some problems, since a single rig cannot drill in cohesionless soil beneath the water table.

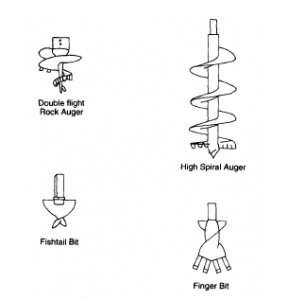

Flight augers may be classified as short-flight augers or continuous- or conveyor-flight augers. Short augers consist of only a few turns of flight above cutting teeth or a hardened steel edge. A high-spiral auger may contain three or four turns of flight. The hole is made by forcing the auger downwards at the bottom of the hole, while rotating it. The cutting teeth break up the soil or rock, which is then transferred up the auger flights. When the flights become full, or when the auger has been advanced for the height of the flights, the auger is raised to the top of the hole and the soil flung clear by rapidly rotating it. Once again, the auger is supported by a Kelly rod which transmits the torque and downward thrust from the drill rig to the auger.

The principal limitation of short augering is that the hole depth is restricted to the length of Kelly rod which the rig can handle. For many of the rigs commonly in use this is only 3—6m. The use of a crane-mounted auger piling rig will allow holes to be drilled to 20—30m if a telescopic Kelly rod is fitted, but as already noted such rigs are very expensive.

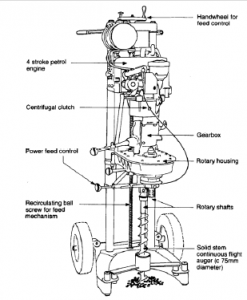

The problems of deep drilling with short augers are largely overcome by the use of continuous or conveyor augers. Continuous augers can be classed as: (i) solid stem continuous-flight augers or (ii) hollow stem continuous-flight augers.

Solid-stem continuous-flight augers allow much deeper holes to be drilled with fewer problems. With this type of auger the Kelly never enters the borehole, as the auger flights extend to above ground level. As the auger is rotated and pushed downwards the soil removed from the base of the hole travels up the flights and emerges at the ground surface. Although this type of auger apparently overcomes the problems found in drilling deep holes with short-flight or bucket augers, it presents a serious problem in site investigation because soil moving up from the base of the hole is free to mix with the soil at higher levels on the edge of the borehole. Thus while auger tailings from short-flight augers or bucket augers may be fairly representative (even if highly remoulded), the soil emerging from the top of a continuous-flight auger will be of no use. In addition, in common with all the auger methods above, the need for casing in granular or other collapsing soils presents a problem. In fine-grained soils a casing can be inserted when collapsing soil is encountered, and can sometimes be advanced by jetting; but in coarse gravels the continuous-flight auger is unusable because it must be removed each time a sample or in-situ test is to be carried out. At this stage the hole will collapse.

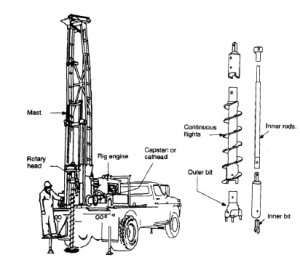

Hollow-stem augers consist of an outer spiral continuous flight with a separate inner rod which blocks off the base of the hole when the auger is being advanced. Both the outer flights and the centre plug are furnished with a bit at the base. The auger is forced into the ground in the same way as a solid-stem auger, with the inner and outer sections rotating together. When samples are required, the inner rods and plug are removed and samples can be taken from the material below the base of the auger. Hollow-stem auger drilling would at first sight seem to be the ideal method of producing site investigation holes, because it is often fast and reliable. There are, however, several problems which should be considered.

First, fissured clays or soils with fabric require relatively large samples for the determination of undrained shear strength and consolidation properties. This means that the hollow stem of the auger must have a large internal diameter (typically 140— 150mm to allow the use of U100 sampling). This in turn means that a relatively powerful and therefore large drilling rig is required. Even if such a rig is available, access to the site of the borehole may be a problem.

Secondly, there are considerable dangers of disturbing soil ahead of the auger if the driller is overeager in soft or firm soils. Heavy downward thrust may cause the auger to be forced into the soil, displacing material ahead of it instead of boring through it. The hand auger provides a light, portable method of sampling soft to stiff soils near the ground surface.

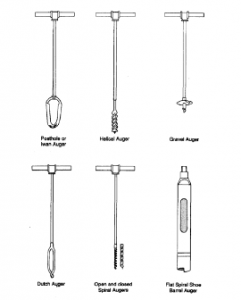

At least six types of auger are readily available:

posthole or Iwan auger;

small helical auger (wood auger);

dutch auger;

gravel auger;

barrel auger; and

spiral auger.

Shows a selection of these augers.

Hand augers are used by one or two men, who press down on the cross-bar as they rotate it thus advancing the hole. Once the auger is full, or has collected sufficient material, it is brought back to the surface and the soil removed. Although the method is cheap because of the simplicity of the equipment, it does suffer from several disadvantages.

The most commonly used auger for site investigation is the ‘Iwan’ auger. This is normally used at diameters of between 100 and 200 mm. Small helical augers are quite effective in stiff clays, but become difficult to use once the water table is reached.

Barrel augers are now rarely seen, but were formerly used with the light percussion rig when progress through clays was made using a shell. They allowed the base of the borehole to be very effectively cleaned before sampling took place. Because they are heavy they require a tripod for raising and lowering them in the borehole. When lowered to the bottom of the hole they were turned by hand (see Harding 1949).

In stiff or very stiff clays, hand-auger progress will be very slow, and the depth of boring may have to be limited to about 5 m. When such clays contain gravel, cobbles or boulders it will not normally be possible to advance the hole at all. In uncemented sands or gravels, it will not be possible to advance the hole below the water table, since casing cannot be used and the hole will collapse either on top of the auger (which makes it difficult to recover the auger from the hole) or when the auger is being removed. Only samples of very limited size can be obtained from the hole. In addition, it will not be possible to carry out standard penetration tests without a frame to lift the trip hammer and weight, so that no idea of the relative density of granular deposits can be obtained.

Despite these difficulties, where access for machinery is impossible the hand auger may give valuable information.

source: www.geotechnique.info