Soil boring with Rotary drilling

Rotary drilling uses a rotary action combined with downward force to grind away the material in which a hole is being made. Rotary methods may be applied to soil or rock, but are generally easier to use in strong intact rock than in the weak weathered rocks and soils that are typically encountered during ground investigations.

For a detailed description of equipment and methods the reader is referred to Heinz (1989).

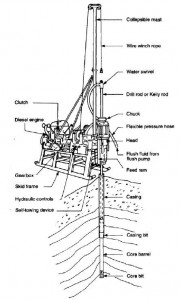

Rotary drilling requires a combination of a number of elements:

1. a drilling machine or ‘rotary rig’, at the ground surface, which delivers torque and thrust;

2. a flush pump, which pumps flush fluid down the hole, in order to cool the mechanical parts and lift the ‘cuttings’ of rock to the ground surface as drilling proceeds;

3. a ‘string’ of hollow drill rods, which transmit the torque and thrust from the rig, and the flush fluid from the flush pump to the bottom of the hole; and

4. a drilling tool, for example a corebarrel, which grinds away the rock, and in addition may be designed to take a sample.

Open-holing

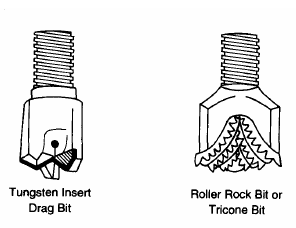

Rotary methods may be used to produce a hole in rock, or they may be used to obtain samples of the rock while the hole is being advanced. The formation of a hole in the subsoil without taking intact samples is known as ‘open-holing’. It can be carried out in a number of ways, but in site investigation a commonly used tool is the ‘tricone rock roller bit’ (or roller core bit). In site investigation such methods are usually used to drill through soft deposits, which have been previously sampled by light percussion or auger rigs. Sampling during open-holing is usually limited to collecting the material abraded away at the bottom of the borehole, termed ‘cuttings’, as it emerges mixed with ‘flush fluid’ at the top of the hole.

Coring

The most common use of rotary coring in ground investigations is to obtain intact samples of the rock being drilled, at the same time as advancing the borehole. To do this a corebarrel, fitted with a ‘corebit’ at its lower end, is rotated and grinds away an annulus of rock. The stick of rock, the ‘core’, in the centre of the annulus passes up into the corebarrel, and is subsequently removed from the borehole when the corebarrel is full. The length of core drilled before it becomes necessary to remove and empty the corebarrel is termed a ‘run’.

Coring equipment

The manner in which the rock is abraded away, and by which the cuttings formed by this process are taken to ground level having been discussed, it becomes necessary to discuss the machinery used for the job. At the base of the borehole a bit is rotated against the rock, thus advancing the hole. This bit can be either solid or annular, depending on whether a sample is required. Annular corebits are screwthreaded to the bottom of a ‘corebarrel’, of which is a typical example in use in site investigation. The corebarrel is screwthreaded to a ‘string’ (i.e. several lengths screwed together) of ‘drill rod’, which is generally of smaller diameter than the corebarrel. The function of the rods is to deliver torque and downward force to the bit (via the corebarrel) while at the same time providing the flush fluid to the bit. The drill rods are therefore hollow.

At ground level, the rods emerge from the hole and pass through the ‘chuck’ of the rig. The chuck grips the drill rods or ‘Kelly’ and transfers longitudinal and rotational movements to the rods. The Kelly continues upwards and is connected to a ‘water swivel’ or ‘gooseneck’, which connects the water or flush hose from the flush pump while allowing the rods to rotate and the hose to remain stationary.

Drill rigs may vary considerably in size and design. Some of the smallest (for example the Acker 1200 PM) mount directly on top of 2.5—4 in. drill pipe (casing) installed by other means to rockhead. They consist of a small four-stroke petrol engine, typically of less than 10 h.p., which connects via a gearbox to the top of the rods. The water swivel is built into the machine, and feed is controlled by a mechanical system operated by a handturned wheel. Quite clearly, such a rig has a very limited capability. The load applied to the bit cannot be controlled, and the rig has no inbuilt hoist for lifting the drilling equipment out of the hole.

Most rotary drilling rigs used in site investigation tend to be rather small, when compared with the very large rigs used for oil exploration. They usually incorporate:

1. hydraulic feed control;

2. multispeed forward and reverse rotation;

3. cathead, wire drum hoist, or both;

4. a mast or tripod; and

5. variable mounting options, for both the rig and the drilling head.

Hydraulic feed control is used to vary the pressure between the corebit and the rock being drilled. In soft rocks, the use of excessive pressure will fracture the rock before it can enter the corebarrel, while in hard rocks the use of low feed pressures will result in very slow drilling progress. In very soft deposits the weight of the rods and barrel may be sufficient to fracture the rock and the hydraulic feed may need to be reversed to hold up the rods.

Multispeed forward and reverse rotation is important both from the point of view of good drilling and convenience. Slow speeds of the order of 50 r.p.m., are required for augering, and open-holing with the tricone. Faster speeds, of up to 1000 r.p.m. may be used for rotary coring, depending on the rock type and bit in use. Reverse is useful either for unsnagging or backing out auger tools or ‘breaking’ rods.

For shallow rotary work, or where augering is being carried out, a cathead is used to lift the drilling tools in or out of the hole. A rope attached to the tools or rods requiring lifting is taken up the rig to the top of the mast or tripod, passed over a pulley, and then brought down to the cathead. The cathead consists of a drum which rotates at constant speed. The rope is given two or three turns around the cathead, but because the drum is smooth it does not grip and pull on the rope. The cathead is made to lift the tools by the operator pulling on the free end of the rope. This tightens the rope on the drum, and the friction then acts to pull the rope and lift whatever drilling tools are attached. The cathead normally has limited lifting power, but perhaps more importantly, fine control requires considerable skill.

In situations where greater lifting capacity or finer control of lifting are required a wire drum hoist is normally used. This is particularly necessary when long strings of drill rods or augers are being lifted.

Smaller rigs, such as the Craelius D750 or Boyles BBS 10 provide the rotation of the rods via a bevel gear, which drives an octagonal spindle. Hydraulic feed is then developed by a piston on each side of the spindle, which pulls the spindle down by acting on a crosshead. Rigs with this configuration usually have a limited stroke:

Acker ADII 1.80 m.

Acker Hillbilly 600 – 900 mm.

Craelius D750 500 mm.

Mobile B31 1.73 m.

Mobile B53 1.98 m.

Since the corebarrels normally used for rotary work in site investigation are 1.5 m or 3.0 m long these rigs cannot drill the complete length of the corebarrel without having to rechuck; that is to undo the chuck, move it up the rods and reclamp it. To do this, rotation of the corebarrel must be stopped and restarted. This inevitably leads to the exposure of the rock being drilled by the bit to the flush fluid for a longer period than during drilling, and any bad effects of the flush fluid will be emphasized at points on the core where rechucking has taken place.

It can therefore be argued that a long-stroke rig will give much better results when coring soft rocks than the type of rig described above. One type of machine which provides a very long stroke for core drilling is the Acker MPIV hydraulic top drive rig. The rotary action is provided by an hydraulic motor, connected to the engine by flexible hose, which can travel long distances up the mast. The feed is provided by a mechanical system. The Pilcon Traveller 30 and Traveller 50 rotary drilling rigs are examples of lightweight machines capable of drilling a 3 m run without rechucking.

The most common mounting options for site investigation are skid mounting, trailer mounting and lorry mounting. In the UK access is normally poor and many contractors use either trailer or skid mounting. In the Middle East and the USA many more rigs are lorry mounted.

The corebarrel is the normal equipment for recovering samples of rock in site investigation. In its simplest form (as used, for example, to obtain cores of concrete), the corebarrel consists of a single tube with an abrasive lower edge which is loaded and rotated while a flush fluid is passed around the bit under pressure. In this process, first the core inside the barrel is subjected to rotative forces due to the friction of the inside of the barrel against the outside of the core, because the core (being attached to the parent material) does not rotate. Secondly, the flush fluid passes over the surface of the core continuously while it is inside the barrel during drilling.

The effect of the first mechanism is to tend to rotate the core at any points of weakness, such as bedding planes in rock. When rotation of the upper part of the core occurs at such a discontinuity a considerable length of core may be ground away, and a distinctive pattern of circular striations (often called a ‘rotation’) can be seen on the end of each stick of core.

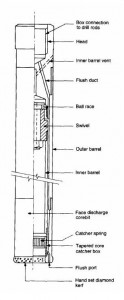

When the flush fluid passes continuously over the core inside the barrel, erosion will occur. This will be particularly serious in soft rocks, where the flush fluid (particularly if water) will tend to soften the outside or along fissures in the stick of core and may well lead to total disintegration of a rock such as soft shale. To counteract these two effects the double-tube, swivel type corebarrel is now used as standard in the UK. shows a typical example. It consists of the following.

1. An outer barrel, connected to the drill rods and drilling rig above.

2. An inner barrel connected to the outer tube at the top via a swivel which allows the inner barrel to remain stationary while the outer barrel is rotated. Flush passes down the barrel between the inner and outer barrel.

3. A reaming shell attached to the base of the outer barrel. This is intended to enlarge the hole produced by the corebit, so that wear on the upper part of the barrel is reduced.

4. A corebit attached to the lower end of the reaming shell. The corebit can be one of many different types, and the illustration shows a face discharge bit.

5. A core lifter or catcher. This device prevents the core from dropping out of the base of the barrel as it is lifted at the end of the run. It consists of:

i the catcher box, which is an open-ended cylinder which tapers downwards, and is of slightly greater diameter than the rock core; and

ii the catcher spring, which fits inside the catcher box and is fluted or grooved so as to grip the rock core. The catcher spring is cylindrical in shape and has an inside diameter slightly smaller than the diameter of the rock core. The wall of the cylinder is cut through at one point, to allow the spring to expand. When the core tries to drop out of the barrel the spring travels down, and is compressed against the core by the inside taper of the catcher box. Thus the greater the downward force, the more friction is developed between the core and the spring.

Triple-tube barrels are identical to double-tube barrels except that a tight-fitting liner tube is used inside the inner barrel. This may be made of stainless steel, or of brass, but in recent UK practice has been composed of clear plastic tube (‘Coreline’). A previously used alternative was Mylar sheet, a thin clear plastic sheet which was held at the lower end of the barrel by a special retainer clip. When using a triple tube, the internal diameter of the catcher and corebit must, of course, be reduced to suit. The advantages of using a third barrel are primarily that the core can easily be withdrawn from the corebarrel, at the end of a run, by pulling the inner liner while holding the barrel horizontally, and that the core can be stored in the liner without disturbing it from its position when drilled. Disadvantages are that the driller cannot immediately see how much recovery he has achieved, and that the engineer or geologist logging the core must cut the liner (usually with a disc cutter) before he can start work. On balance, the use of Coreline seems to have produced a significant improvement in the quality of core available for logging.

Retractor barrels have inner barrels which are spring-mounted, and protrude ahead of the kerf of the bit, in order to provide some protection for the core from the flush. Notable examples are the Mazier and Triefus barrels

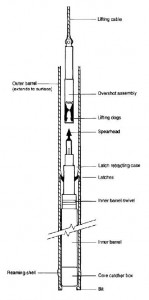

Wireline drilling is a technique which has been widely used for deep mineral drilling for many years, principally because it reduces the trip time (i.e. the time necessary to extract the corebarrel from the bottom of the hole, empty the core and replace the barrel). This technique has, in the past ten years, become well established on high quality ground investigations, and has proved particularly effective in the coring of relatively difficult deposits, such as overconsolidated clays, chalks, and interlayered sands, gravels, limestones and clays.

Wireline drilling is a technique which has been widely used for deep mineral drilling for many years, principally because it reduces the trip time (i.e. the time necessary to extract the corebarrel from the bottom of the hole, empty the core and replace the barrel). This technique has, in the past ten years, become well established on high quality ground investigations, and has proved particularly effective in the coring of relatively difficult deposits, such as overconsolidated clays, chalks, and interlayered sands, gravels, limestones and clays.

Wireline drilling does not use any outer casing, but instead uses an outer barrel which extends at full diameter to ground level (Fig. 5.12). The inner barrel is lowered through the full length of the outer barrel, on a wire line. When it reaches the bottom of the hole it latches inside the outer barrel, in the correct vertical position. The outer barrel is then turned by the rig, as flush is pumped down it. The latching mechanism holds the inner barrel down, but does not fix it so that it must rotate with the outer barrel. When the outer and inner barrels have been drilled for the length of the run, the wire line is winched upwards, and the latching mechanism automatically disengages the inner barrel from the outer. The inner barrel and core are hoisted to ground surface, where the core is extracted and a new length of outer barrel is added to the string.

In principle, wireline coring is considerably simpler than conventional double-tube swivel type coring. No casing is used, and there is no swivel to become jammed. In practice, however, the rig used must be considerably heavier than for conventional drilling, because of the torque required to turn the outer barrel, which is in contact with the ground for the entire depth of the hole. Lorry-mounted rigs are the norm. In addition, the bit on the outer barrel can only be changed at the expense of considerable loss of production. It is preferable to use a single bit for the entire length of the hole. Therefore bit wear, and the choice of a type of bit appropriate to the ground conditions are important factors.

Scarrow and Gosling (1986) describe the extensive use of SK6L wireline drilling (producing a core diameter of 102 mm) in the alluvial valley at Baghdad, Iraq. As might be expected, the soils encountered were very variable, consisting mainly of clays, silts and sands, with some gravel being present. Wireline techniques were used in conjunction with polymer drilling mud (see below). Care was taken to restrict the pumping rates, to keep erosion of granular soils in the bit area to a minimum. A constant fluid level was maintained in the borehole at all times, and especially when the corebarrel was being returned to the surface, and the corebarrel was raised and lowered slowly, in order to minimize suction effects and pressure surges, and therefore the chance of piping and base heave

BITS

The selection of the right corebit for the job is a rather difficult task. The variables in a corebit design are:

. face contour;

. cutting material;

. diamond types, grades and sizes;

. mounting matrix;

. waterway size, shape and position; and

. ‘kerf’ width.

The face of the bit may vary from a ‘flat’ surface to a ‘full-round’ surface, where the radius of the surface is equal to half the ‘kerf’ width (i.e. half the thickness of the diamond inset part of the bit). In practice most bits are semi-round or semi-flat in design.

The cutting material may be tungsten, diamond impregnate, or hand-set diamonds. Tungsten bits usually have large tungsten inserts mounted radially across the kerf. This type of bit can only be used for drilling very soft formations, such as soft shale or coral. However, the coarseness of the inserts

increases the bearing pressure on the rock, and may well lead to a disturbance and fracture ahead of the bit. This type of bit is also used for casing.

Diamond impregnate bits consist of a sintered powder metal matrix with fragmented or fine ‘Bortz’ (i.e. low grade industrial diamonds) embedded uniformly throughout it. As the matrix wears down, new sharp diamonds are exposed. This type of bit is suitable for hard rocks, and may often be used for casing shoes where casing has to be advanced into the rock.

The best quality diamond bits contain hand-set selected Bortz. The diamonds are of selected size and grade and are placed in the matrix by hand, with the hardest vector of each diamond facing in the direction of the work. This type of bit differs from tungsten or impregnate bits because with the former the bit is used until the ‘crown’ (i.e. the part of the bit formed of the matrix, and set with diamond or tungsten) is consumed. A Bortz-set bit is only used until either the diamonds become polished, or the matrix is abraded around the Bortz to the point where they are over-exposed. At this stage the diamond bit is returned to the manufacturer, where the diamonds are removed and reset.

The quality of diamonds used in the bit varies. Diamonds are also sometimes classified on a geographical basis, such as ‘West Africans’, ‘Congos’, ‘Brazilians’, ‘Angolans’, etc. This means only that the diamonds resemble the typical products of these areas. Congos and West Africans are commonly used in drilling bits, with a preference for West Africans. According to Boyles Bros Diamond Drilling Terms and Equipment Standards, Congos were previously only considered for use in broken form, but more recent applications seem to use them as large stones.

The size of diamond in use in the bit should be tailored to the soil or rock being drilled. In soft material or fractured and weathered near-surface rock large Congos may be used, because the large size has good clearance and allows good washing without blocking the bit. Large diamonds are also apparently more capable of surviving the shocks administered during drilling fractured rock. As the rock becomes harder, smaller and more numerous diamonds are necessary to provide more cutting edge and therefore keep progress at a reasonable level. In addition, the use of more diamonds provides an even load distribution on the bit. The weight of a stone is measured in terms of its ‘carat’ where 1 international metric carat = 200 mg. The ‘carat weight’ is the total weight of diamond set in the bit, which may be between 5 and 50 carat depending on bit size.

The matrix must hold the diamonds in the required position, resist shock, and transfer heat away from the diamonds. The property often used to classify the abrasion resistance of the matrix is hardness, sometimes measured on the Vickers or Rockwell scale. This is not a perfect classification method because hardness is not directly related to either abrasion resistance or the other properties mentioned above.

The design of the waterways also depends on the type of rock to be drilled, and in addition on the flush fluid. Air or mud flush require larger size or more passageways. Soft formations require multi-waterway bits to allow the quick removal of cuttings before blocking occurs. Once the waterways have blocked then not only will the bit overheat, and therefore undergo excessive wear, but the core will also be seriously damaged. In hard rock the cuttings are of finer size and are more granular in nature. Fewer waterways need to be incorporated, and in some cases when drilling very easy materials no waterways are used.

Two types of bit are available: normal or face (bottom) discharge. In normal discharge bits all the flush passes down between the inner and outer barrels, outside of the catcher box, and out of the barrel between the core and the bit. The contact of the flush water with the core, even for this short distance, can have a serious effect and in soft deposits face or bottom discharge bits are commonly used. The drilling bit has ports in the lower end (the face) and the majority of the flush fluid is therefore discharged away from the core, flowing to the outside of the bit.

The face discharge bit represents an improvement on the conventional bit, but suffers from some disadvantages:

1. flush fluid is still allowed to make contact with the core; and

2. over-eager drilling may lead to the ports becoming blocked, especially when drilling in soft rocks or hard clays. Under these conditions it may be necessary to apply no downward pressure to the rods, or in extreme cases even to hold the rods up to reduce the pressure on the face.

One method of overcoming the problems of over-stressing and port blocking may be to use a step-taper bit.

Flush fluid

Flush fluid is passed around the bit while drilling proceeds. The purpose of the fluid is:

1. to remove the cuttings from the borehole;

2. to cool the drilling bit, and drill rods;

3. to reduce mechanical and fluid friction; and

4. to help to retain an open hole wherever possible, without the use of casing.

At the same time, the flush fluid should not encourage the softening or disintegration of the cores, which are the purpose of drilling. A large number of different types of flush fluid are in use, but they are generally classed as:

. water-based (for example water, bentonite/water (drilling mud));

. oil-based;

. air (or mist); and

. stable foam.

The most common flush fluid in use in British site investigation is water, with air being used when water causes serious softening of the formation being drilled. Water is, however, by no means the ideal fluid.

Most drill rigs use normal circulation; that is the flush fluid is pumped down through the drill rods, passes outwards over the bit and travels upwards in the annular space between the drill rods and the outside of the hole carrying the cuttings with it (Fig. 5.9). The requirement of removing cuttings from the base of the hole requires either viscous flush fluid or high flush velocity to maintain the cuttings in suspension.

sorce: www.geotechnique.info

Previous Post

Previous Post Next Post

Next Post